"CRYOTECH" Projects - Vacuum and Cryogenic Technologies in Uzbekistan

Engineers at "CRYOTECH" have successfully completed numerous projects involving commissioning, installation, and modernization of equipment at leading enterprises in Uzbekistan and the CIS countries.

SPACE SIMULATORS

Our role in this project involves a vacuum system for degassing the thermal simulator circuit and evacuating the vacuum chamber. An important feature is that the vacuum system must connect to volumes under positive pressure and be able to start and begin evacuation under these conditions.

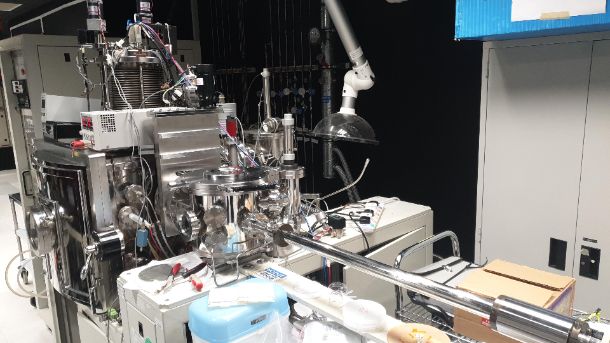

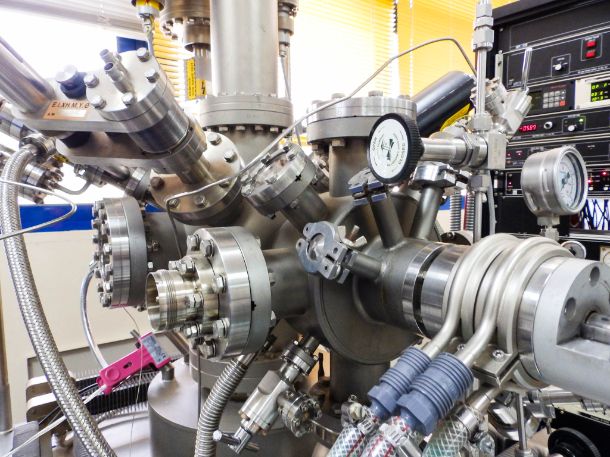

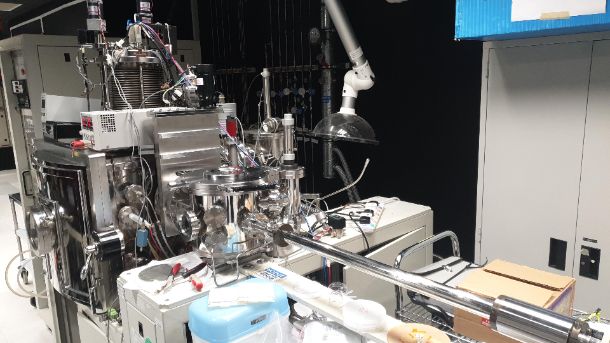

RESEARCH INSTALLATIONS FOR HIGH-TECH APPLICATIONS

The vacuum evacuation system designed and installed by CRYOTECH staff achieves a transition from atmospheric pressure to a working pressure of 1x10^-4 Torr in less than 20 minutes for a facility with a useful volume of 40 m³.

CRYOGENIC INSTALLATIONS AND RESEARCH LOW-TEMPERATURE CRYOSTATS

In June 2015, with our direct involvement, commissioning work was conducted, and the successful launch of the L-280 helium liquefier (manufactured by Linde Kryotechnik AG) was achieved.

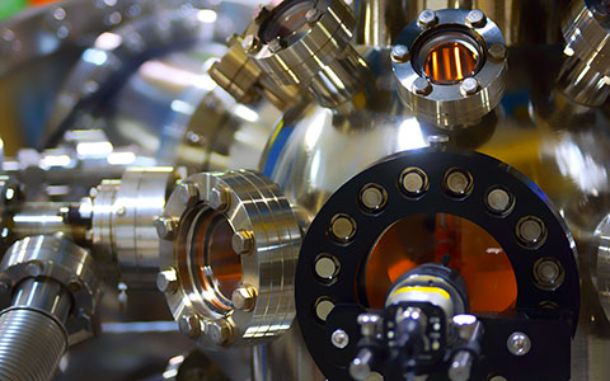

MODERNIZATION OF THE VACUUM CHAMBER

The modernization of the vacuum chamber is being undertaken to achieve a vacuum level of 1+10^-6 Torr.

AUTOMATED LEAK TESTING STAND

The stand is designed based on a cylindrical stainless steel chamber with water-cooled walls. An integrated helium supply system allows for regulation of the helium pressure increase rate both within the chamber and in the test object. Heating of the product in the vacuum chamber is achieved using infrared radiation up to a temperature of +400 °C.

CVD SYSTEM (Chemical Vapor Deposition)

Completion of assembly and testing of the control program for the Chemical Vapor Deposition (CVD) system for depositing structures such as Bismuth Telluride.